Repairing shaft seal leaks

by Phil Lapin / CPPC Tech Committee and President

Some of you avid mechanics will know all about this month's topic – but for others this may be new and valuable information. I might joke that "I have something up my sleeve for you" – read on and you will understand.

Vehicles have moving shafts on them – and many of those shafts need a barrier between the inside of some fluid filled enclosure and the outside world. Water pumps have seals to form this barrier. Differentials, transmissions, engines and axles are some other examples where seals need to be employed. Most of these situations involve oils of some type – and that oil must not leak out of the casing it is inside. Vintage autos – some well over 70 or 80 years old, used rather primitive seals around shafts – even incorporating leather and felt. When they begin to leak, the task of replacing them can provide some challenges.

Vehicles have moving shafts on them – and many of those shafts need a barrier between the inside of some fluid filled enclosure and the outside world. Water pumps have seals to form this barrier. Differentials, transmissions, engines and axles are some other examples where seals need to be employed. Most of these situations involve oils of some type – and that oil must not leak out of the casing it is inside. Vintage autos – some well over 70 or 80 years old, used rather primitive seals around shafts – even incorporating leather and felt. When they begin to leak, the task of replacing them can provide some challenges.

First, old style seals need to carefully examined to find identifying number codes. Most will have this, but don't expect to find a new modern replacement which still has leather for the seal. With the same dimensions and fit, a modern seal with usually have some type of rubber material forming the seal surface. There may also be improvements employing more than one sealing surface. You can certainly chase down a "NOS" original seal from some source, but why? The sealing surface may be old and brittle, plus being less effective than a modern design.

The Internet can be a valuable tool for finding seals on your own – often by simply Googling in the original part identification. With a modern part cross referenced, it is often easy to find an auto parts store that can get what you need.

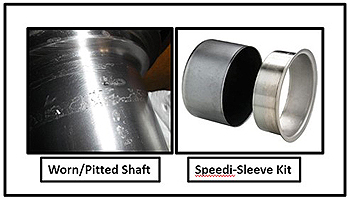

No replacement seal made will work well if the shaft it seals around is not in excellent condition. This is where a major problem comes into play. Vintage shafts can have wear grooves, rusting or pitting where the seal contacts them. If dust and dirt have accumulated around the old seal, sometimes amazing grooves can be worn into the shaft. Moisture or sitting will also allow for the rusting and pitting often encountered. Correcting these defects can be much easier than one might expect – and at reasonable cost.

There is a great invention known by several names which will restore damaged shafts. A popular brand is "speedi sleeve". This product consists of a stainless steel sleeve that fits over the damaged portion of the shaft. The wall thickness of these sleeves is only about .010", so a standard seal can still be used on the shaft. The sleeves come in a continuous range of diameters, each of which will fit a given shaft with about .005" in tolerance. Just look up the shaft diameter in a table, and order accordingly. The "kit" you will get typically has the sleeve with an integral flange on one end that can be removed. A metal "cup" is also included, which is used to tap the sleeve into place over the shaft. The fit is tight, and the result is a very smooth new surface. Check around for the best price on these (including Amazon). Most automotive sizes run between $35 - $50. / P.L.